This is the first of two video segments about applying fiberglass to the hull using polyester resin.

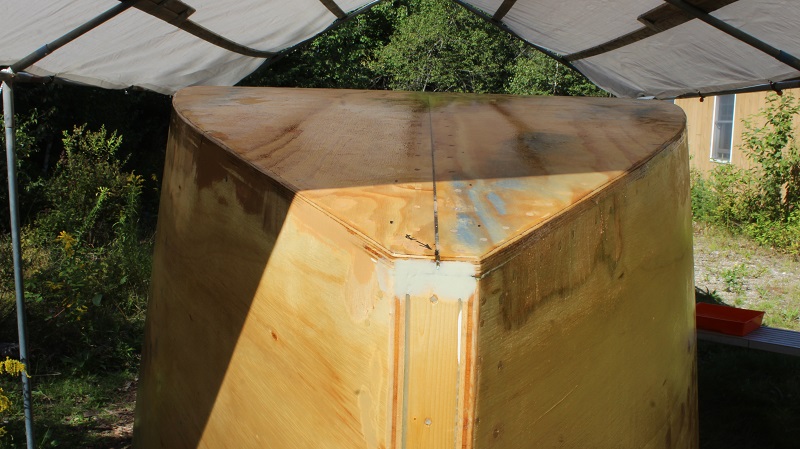

I begin the application by covering the bare plywood hull with two coats of (no wax) polyester laminating resin that has been thinned out with 7% Styrene and catalyzed with 2% MEKP (by volume). This operation takes place to allow the resin to “soak” into the plywood such that more cohesive bond will take place when the glass is applied and reduces the risk of fiberglass cloth de-lamination from the plywood.

I then begin applying fiberglass tape along the plywood seams such as the chine, around the transom, and the stem. In this step, I use (no wax) polyester laminating resin, but it is not thinned with Styrene. A third coat of resin is applied before the glass tape is put in place, then additional resin is rolled in over the top of the glass. I then use a fiberglass rolling tool to work out any air bubbles that may surface.

Here’s the video: